Khởi động từ NXC-185 3P 185A 2NO+2NC 220Vac 50/60Hz Chint:

Complete Technical Guide

Last updated: May 15, 2025

Selecting the right contactor for

industrial applications can significantly impact operational efficiency and

system reliability. The Chint NXC-185 contactor

stands out as a robust solution for controlling large electrical loads in

various industrial settings. This comprehensive guide explores the technical

specifications, applications, and benefits of the Khởi động từ

NXC-185 3P 185A 2NO+2NC 220Vac 50/60Hz Chint, providing

valuable insights for electrical engineers, contractors, and industrial

maintenance professionals.

Technical Specifications of the Chint NXC-185

Contactor

The Chint NXC-185 is a

high-performance 3-pole AC contactor engineered for demanding industrial

applications. It features a substantial 185A rated current

capacity, making it suitable for controlling large motors and

electrical equipment. The contactor operates on a 220VAC coil

voltage with compatibility for both 50Hz and 60Hz frequencies,

ensuring versatility across different power systems.

One of the key advantages of this model is its

auxiliary contact configuration with 2 normally

open (2NO) and 2 normally closed (2NC) contacts. This arrangement provides

enhanced control capabilities and monitoring options for complex industrial

processes. The contactor’s rated insulation voltage of up to

690VAC ensures safe operation even in high-voltage

environments.

Key Specifications at a Glance

| Specification | Value |

|---|---|

| Model | NXC-185 |

| Manufacturer | Chint |

| Rated Current |

185A |

| Number of Poles |

3P (Three-pole) |

| Coil Voltage |

220VAC |

| Frequency | 50/60Hz |

| Auxiliary Contacts |

2NO + 2NC |

| Insulation Voltage |

Up to 690VAC |

| Operating Temperature |

-5°C to +60°C |

| Short-circuit Withstand |

Up to 4kV |

Applications and Use Cases

The Chint NXC-185 contactor excels in

various industrial applications requiring reliable control of high-current

electrical loads. Its robust design makes it particularly well-suited for

motor control applications in manufacturing

facilities, where consistent performance and durability are essential. The

contactor’s high current rating enables it to handle the demanding

requirements of large industrial motors without compromising operational

reliability.

In HVAC systems, the NXC-185 provides

dependable control for compressors and air handling units, contributing to

efficient climate control in commercial buildings. The contactor’s auxiliary

contacts allow for sophisticated control sequences and status monitoring,

enhancing system functionality and safety.

- Industrial

motor control for manufacturing equipment - Pump

systems for water treatment and distribution - Compressor

control in refrigeration and HVAC

applications - Power

distribution panels in commercial buildings - Industrial

machinery requiring frequent starting and

stopping - Elevator

and escalator systems in commercial complexes

“After installing the Chint NXC-185 contactors in our

manufacturing facility’s motor control centers, we’ve experienced a

significant reduction in downtime and maintenance requirements. The robust

design and reliable performance have exceeded our expectations.” –

Senior Electrical Engineer at a leading manufacturing company

Integration with Overload Protection

A key advantage of the NXC-185

contactor is its compatibility with thermal overload relays,

particularly the NXR-200

series. This integration creates a complete electromagnetic starter

solution that provides both switching control and critical motor protection.

When paired with appropriate overload protection, the contactor forms a

comprehensive motor control solution that safeguards valuable equipment from

damage due to electrical faults.

The combined solution offers protection against common issues such

as phase loss, overloading, and short circuits.

This integrated approach enhances system reliability while simplifying

installation and reducing panel space requirements. Engineers can configure

the protection parameters to match specific motor characteristics, ensuring

optimal protection without nuisance tripping.

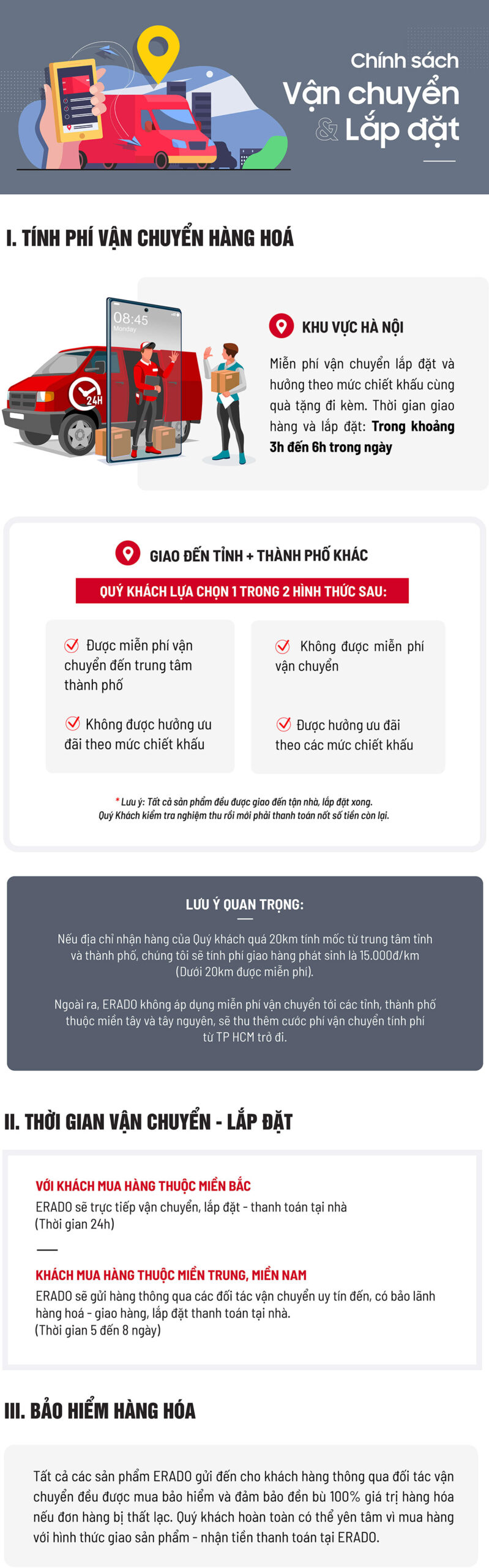

Diagram showing typical connection of NXC-185 contactor

Diagram showing typical connection of NXC-185 contactorwith NXR-200 thermal overload relay

Installation and Mounting Considerations

The Chint NXC-185 features a

compact design relative to its current rating,

making efficient use of valuable panel space. Installation is

straightforward, with clearly marked terminals and standard mounting options

compatible with DIN rails and panel mounting plates. The contactor’s terminal

design accommodates large cable cross-sections required for high-current

applications, ensuring secure connections and minimal heat

generation.

When installing the NXC-185, proper ventilation is essential to

maintain operating temperatures within the specified -5°C to

+60°C range. Adequate clearance around the contactor allows

for efficient heat dissipation and extends operational life. The contactor’s

coil terminals are clearly separated from the power terminals, reducing the

risk of wiring errors during installation.

- Ensure adequate panel

ventilation to maintain proper operating temperature - Verify correct coil

voltage (220VAC) before connection - Use appropriate cable

sizes for the 185A rating - Torque terminal screws to

manufacturer’s specifications - Install surge suppression

devices for coil protection when necessary - Mount securely on DIN

rail or panel mounting plate

Durability and Reliability Features

The Chint NXC-185 contactor is

engineered with exceptional mechanical and electrical

durability, designed to withstand the demands of frequent

switching operations in industrial environments. Its robust construction

includes high-quality contact materials that resist welding and erosion, even

under heavy electrical loads. The contactor’s ability to withstand

short-circuit voltages up to 4kV provides an

additional layer of protection for connected equipment.

The contactor’s coil design ensures reliable operation even under

fluctuating voltage conditions, maintaining proper contact pressure

throughout its operational life. Enhanced arc extinguishing chambers

effectively suppress arcing during contact opening, extending contact life

and reducing maintenance requirements. These reliability features contribute

to reduced downtime and lower total cost of ownership for industrial

electrical systems.

Reliability Highlights:

- High

mechanical durability for frequent switching

operations - Superior

electrical endurance under rated load

conditions - Arc

suppression technology for extended contact

life - Short-circuit withstand capability

up to 4kV - Stable

performance across wide temperature range

Compliance with International Standards

The Chint NXC-185 contactor is

manufactured in compliance with rigorous international standards, ensuring

safety, reliability, and interoperability with other electrical components.

It meets IEC 60947 requirements for low-voltage

switchgear and control gear, demonstrating its suitability for global

industrial applications. The contactor also carries CE

marking, indicating conformity with applicable European

health, safety, and environmental protection standards.

This compliance with international standards provides assurance to

system designers and end-users regarding the contactor’s performance and

safety characteristics. Regular testing and quality control procedures during

manufacturing ensure consistent adherence to these standards. The contactor’s

design incorporates features that facilitate compliance with electrical

safety regulations when properly installed and applied.

Comparison with Similar Products

When compared to similar contactors in its class, the

Chint NXC-185 offers an attractive combination

of performance, reliability, and value. Its 185A current

rating places it in the medium-to-heavy duty category,

suitable for controlling substantial industrial loads. The standard

2NO+2NC auxiliary contact configuration provides

versatility for various control schemes without requiring additional

accessories.

While premium European and Japanese brands may offer slightly

higher mechanical durability ratings, the Chint NXC-185 delivers comparable

electrical performance at a more competitive price point. Its compact

dimensions relative to current rating help optimize panel space utilization

compared to some competing models. The contactor’s compatibility with

standard accessories and mounting options simplifies inventory management and

maintenance requirements.

| Feature | Chint NXC-185 |

Competitor A |

Competitor B |

|---|---|---|---|

| Rated Current |

185A | 180A | 200A |

| Auxiliary Contacts |

2NO+2NC Standard |

1NO+1NC Standard |

2NO+2NC Standard |

| Dimensions (WxHxD) |

Compact design |

10% larger |

Similar size |

| Mechanical Durability |

High | Very High |

High |

| Price Point |

Competitive | Premium | Premium |

Maintenance and Troubleshooting

Regular maintenance of the Chint

NXC-185 contactor helps ensure long-term reliability and performance.

Periodic visual inspections can identify potential issues before they lead to

failures or downtime. Check for signs of overheating, contact wear, or loose

connections during scheduled maintenance intervals.

When troubleshooting the NXC-185, start by verifying proper coil

voltage and examining the contactor for visible damage or wear. Common issues

include coil failure, contact wear, and mechanical

binding. The contactor’s straightforward design facilitates

diagnosis and replacement of worn components when necessary.

Maintenance Checklist:

- Inspect terminals for

signs of overheating or loose connections - Check contacts for

excessive wear or pitting - Verify proper operation

of auxiliary contacts - Confirm coil operation

and appropriate pick-up/drop-out voltages - Clean dust and debris

from contactor surfaces and ventilation openings - Test mechanical operation

and freedom of movement

Energy Efficiency Considerations

The Chint NXC-185 contactor

contributes to energy-efficient operation through its optimized

electromagnetic design and contact materials. The contactor’s coil consumes

minimal power during sustained operation while maintaining reliable contact

pressure. This energy-efficient design helps

reduce operational costs in systems where contactors remain energized for

extended periods.

When used in motor control applications, the contactor’s low

contact resistance minimizes power losses and heat generation. This

efficiency not only reduces energy consumption but also contributes to longer

operational life by keeping operating temperatures lower. For applications

requiring frequent switching, the contactor’s reliable performance helps

maintain optimal system efficiency.

“Implementing Chint NXC-185 contactors as part of our energy

efficiency upgrade has contributed to a measurable reduction in our

facility’s electrical consumption. The contactors’ reliable performance

ensures our equipment operates at optimal efficiency.” – Facility

Manager at a large industrial processing plant

Pricing and Availability

The Chint NXC-185 contactor offers

excellent value considering its performance specifications and reliability

features. It is positioned competitively in the market, providing industrial

users with a cost-effective option for heavy-duty switching applications. The

contactor’s standardized design and widespread distribution network ensure

good availability across global markets.

For current pricing information and availability, contacting authorized Chint distributors is

recommended. Volume discounts may be available for bulk orders, and lead

times typically range from stock availability to 2-3 weeks depending on

location and quantity. The contactor’s standard design minimizes the need for

special ordering or customization in most applications.

Warranty and Support

Chint provides comprehensive warranty coverage for the

NXC-185 contactor, reflecting confidence in its

quality and reliability. The standard warranty covers manufacturing defects

and premature failures under normal operating conditions. Extended warranty

options may be available through authorized distribution channels for

critical applications.

Technical support for the NXC-185 contactor is available through

Chint’s global network of representatives and distributors. Support resources

include technical

documentation, application guides, and access to knowledgeable

technical personnel who can assist with selection, installation, and

troubleshooting. This support network ensures users can maximize the value

and performance of their Chint contactors.

Conclusion

The Khởi động từ NXC-185 3P 185A 2NO+2NC 220Vac

50/60Hz Chint represents an excellent balance of performance,

reliability, and value for industrial electrical systems. Its robust design

and comprehensive feature set make it suitable for demanding applications

across various industries. The contactor’s compliance with international

standards ensures compatibility and safety when integrated into electrical

control systems.

For engineers, contractors, and maintenance professionals seeking

a dependable solution for motor control and power switching applications, the

Chint NXC-185 offers the necessary technical capabilities without unnecessary

complexity or cost. Its straightforward installation, minimal maintenance

requirements, and long operational life contribute to lower total cost of

ownership for industrial electrical systems.

Frequently Asked Questions (FAQs)

Can the Chint NXC-185 contactor be used with

variable frequency drives?

Yes, the NXC-185

contactor can be used in conjunction with variable frequency drives (VFDs),

typically installed on the input or output side depending on the application

requirements. When used on the output side of a VFD, additional

considerations regarding switching frequency and potential voltage spikes may

need to be addressed.

What is the expected mechanical lifetime of the

NXC-185 contactor?

The Chint NXC-185

contactor is designed for high mechanical durability, with an expected

mechanical lifetime exceeding 1 million operations under normal conditions.

This makes it suitable for applications requiring frequent switching

operations. The electrical lifetime will be lower than the mechanical

lifetime and depends on the specific load characteristics and switching

frequency.

Is the NXC-185 suitable for outdoor

installation?

The NXC-185

contactor is designed primarily for indoor installation with an operating

temperature range of -5°C to +60°C. For outdoor applications, the contactor

must be installed within an appropriate enclosure that provides protection

against moisture, dust, and extreme temperatures. The enclosure should meet

the required IP rating for the specific outdoor environment.

Can additional auxiliary contacts be added to

the NXC-185?

Yes, the NXC-185

contactor design allows for the addition of auxiliary contact blocks. These

can be mounted to the side of the contactor to provide additional NO and NC

contacts beyond the standard 2NO+2NC configuration. Chint offers compatible

auxiliary contact blocks that can be easily installed to expand the

contactor’s control capabilities.

What is the recommended replacement interval for

the NXC-185 contactor?

There is no fixed

replacement interval for the NXC-185 contactor, as the actual service life

depends on factors including switching frequency, load characteristics, and

operating environment. Regular inspection of contacts for wear, measurement

of contact resistance, and monitoring of operating temperature are

recommended to determine when replacement is necessary. In critical

applications, some users opt for preventive replacement based on operation

count or time intervals specific to their reliability

requirements.